| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Infi |

| Price : | To be negotiated |

| Delivery Time : | 7 working days |

| Payment Terms : | T/T, Western Union, PayPal |

| Supply Ability : | 100pcs/7days |

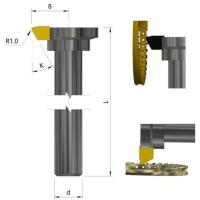

Diamond Helical End Mill | PCD/MCD/CVD

Tool parameter table (mm) | |||||||

D | H | L | d | R | BH | β | F |

1.5-10.0 | 3.0-6.0 | 50 | 4-10 | 0.03 | 5-10 | 1-7 | 1-2 |

1. R&D Objective

Traditional diamond end mills with vertical axial side edges employ

full-width milling, resulting in visible vertical tool marks (feed lines) on machined surfaces. This significantly compromises sidewall

finish quality (typically Ra0.2-0.5μm), failing to meet mirror-finish standards.

2. Features & Advantages

Helical Single-Point Milling:

Modular Design:

Process Optimization:

3. Applications

Precision bottom/sidewall milling

Mirror-finish machining for aerospace turbine blades, medical implants

4. Tool Lifespan

Single-edge: 5x longer vs straight-edge end mills

Double-edge: 10x longer vs single-edge variants

Field Data: 500+ hours continuous operation

5. Market Feedback

100% elimination of feed line defects

94% user satisfaction in luxury watch component production

|